Rapid prototyping and desktop manufacturing are game changers, so I’ve been exploring and creating several exciting, new products.

Question… Using Neopixel LED matrixes and rings (and inspired by a spontaneous “napkin sketch”), Is it possible to successfully design, manufacture, test, market a consumer product from home?

Design Statement

Design an interactive, “smart”, visual lighting experience. Device to be controllable from mobile devices, web browsers and common smart home hubs. 3D printed enclosure to have a good-to-better appearance. Must use ESP32 micro-controller, off-the-shelf Neopixel arrays and through-hole electronic components for ease of assembly. Operating system can be open source or custom. End goal is to have a marketable product.

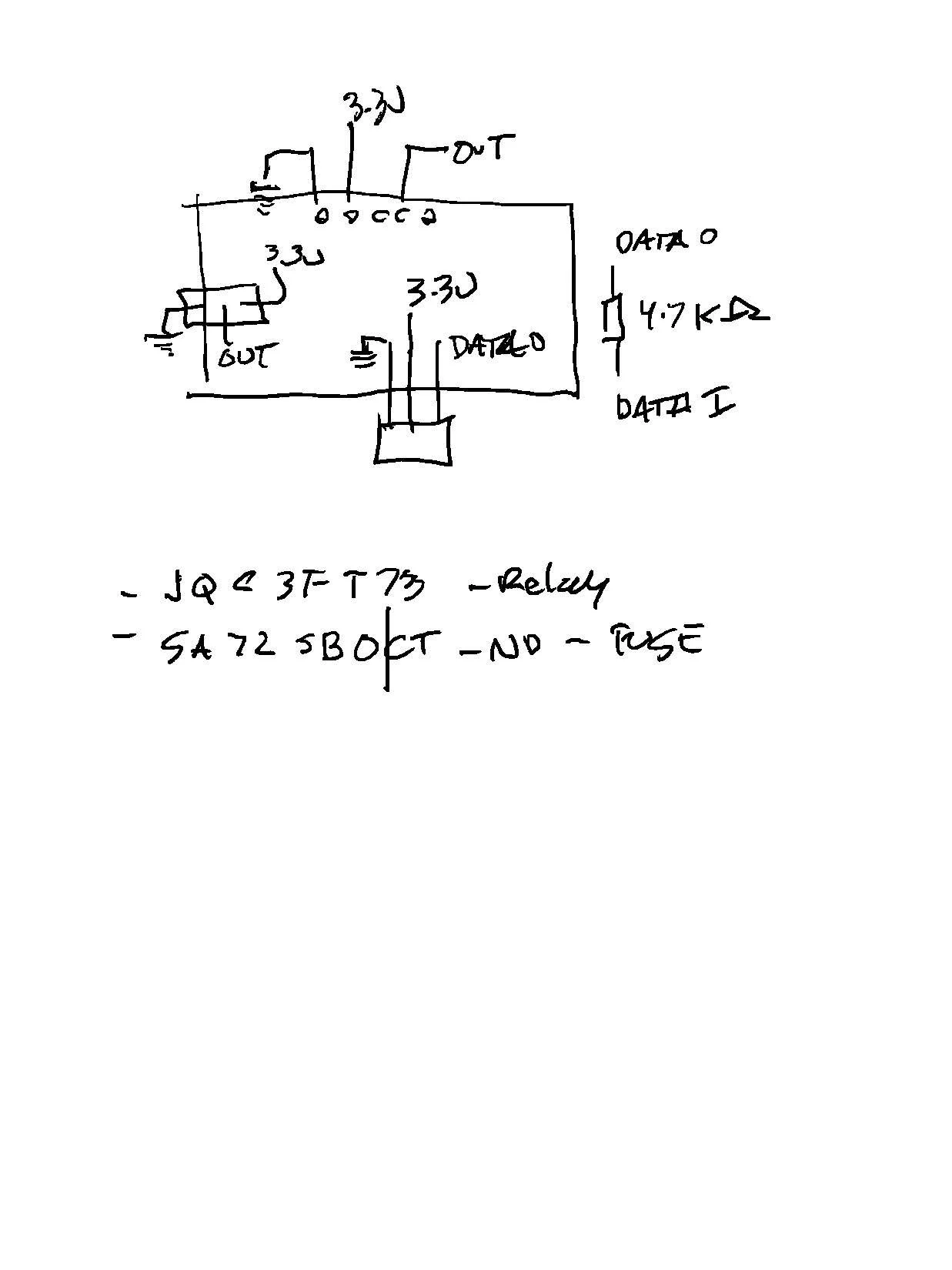

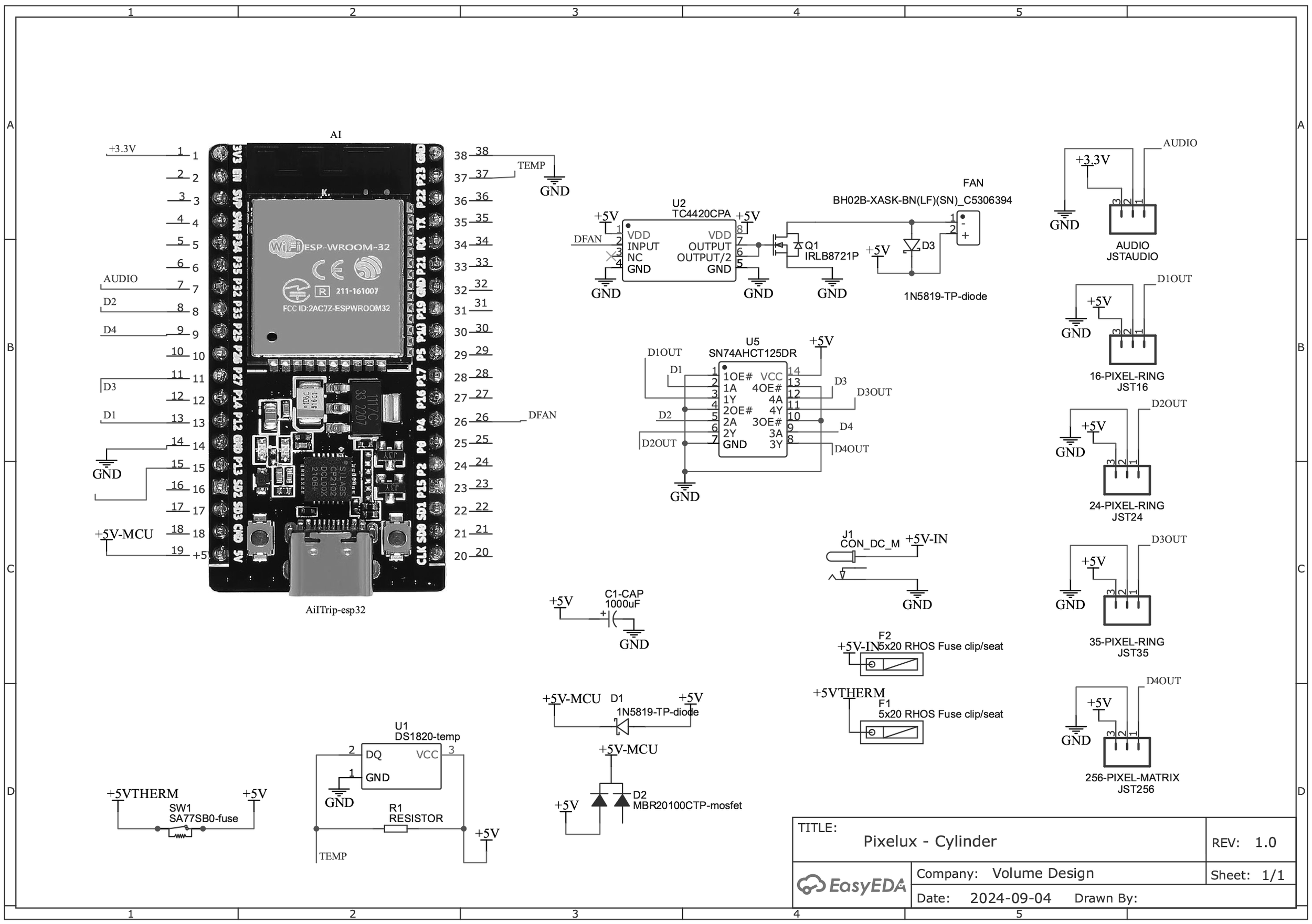

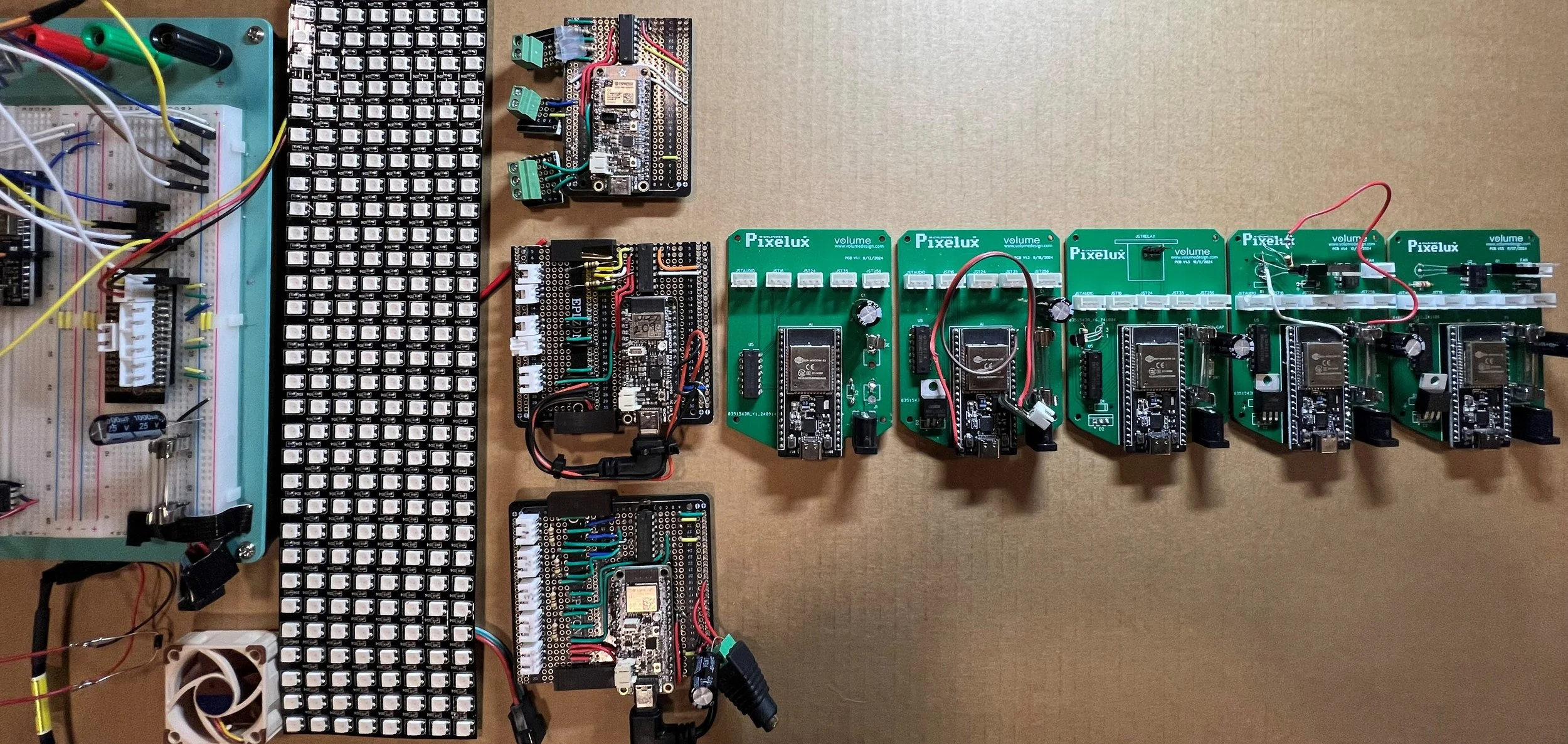

Breadboard and Schematic

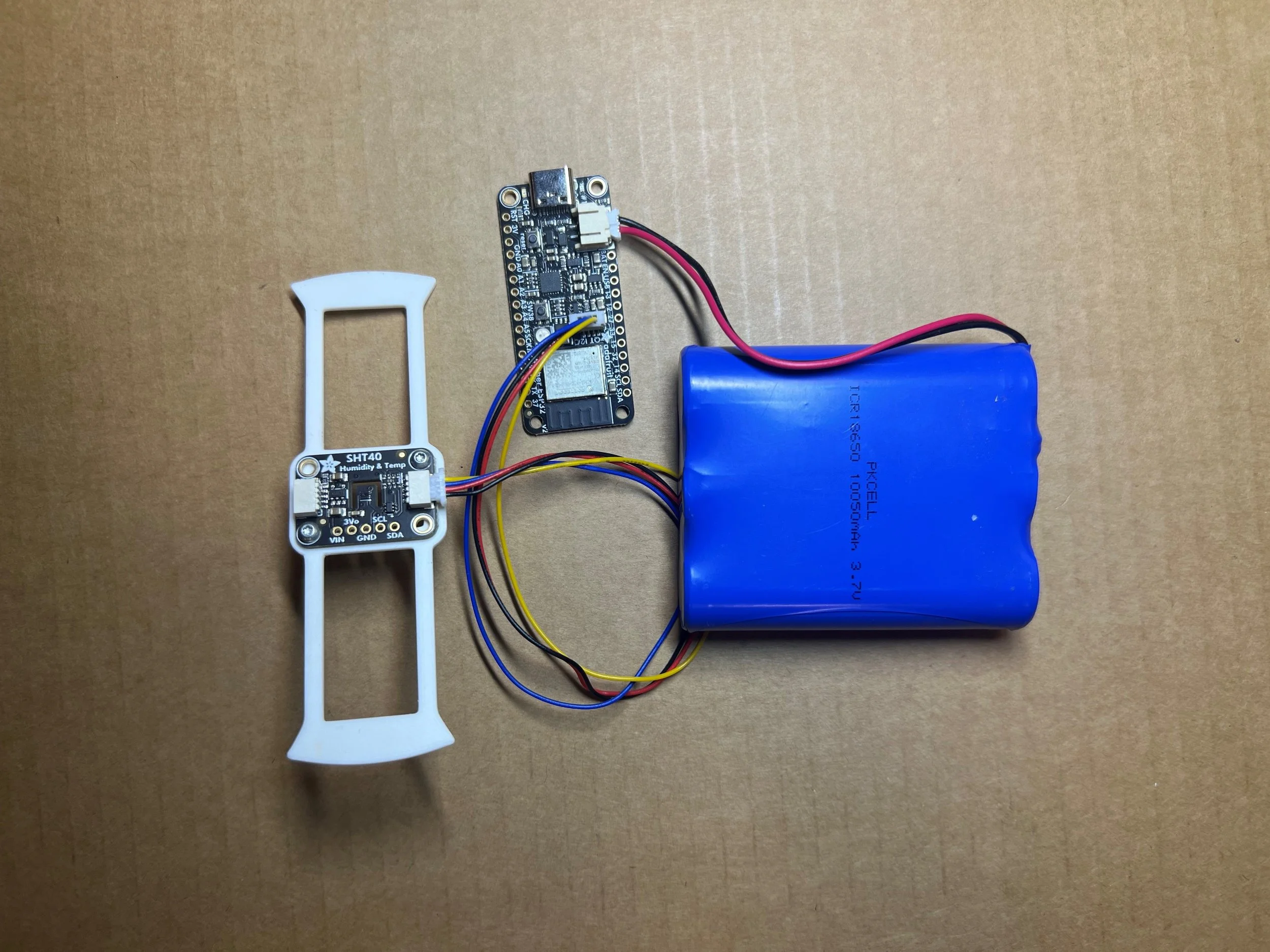

There is much information on the web (and a lot of suspect information on AI chatbots) to fill the knowledge gaps in hardware and software development. Let’s start by breadboarding the internals of the device with the known Neopixel information. We have a 256 pixel matrix and 16, 24 and 35 pixel rings to work with. We’ll need a power source for 5V DC for current and data logic a microcontroller, a capacitor, and some resistors. Later, throw in a couple fuses for safety and a temperature sensor driven PWM fan to keep things cool. A microphone to capture ambient sounds to drive animations would be nice. Oh, and we need to isolate the microcontroller from the rest of the system when it’s on USB

PCB final schematic

PCB evolution

PCB final layout

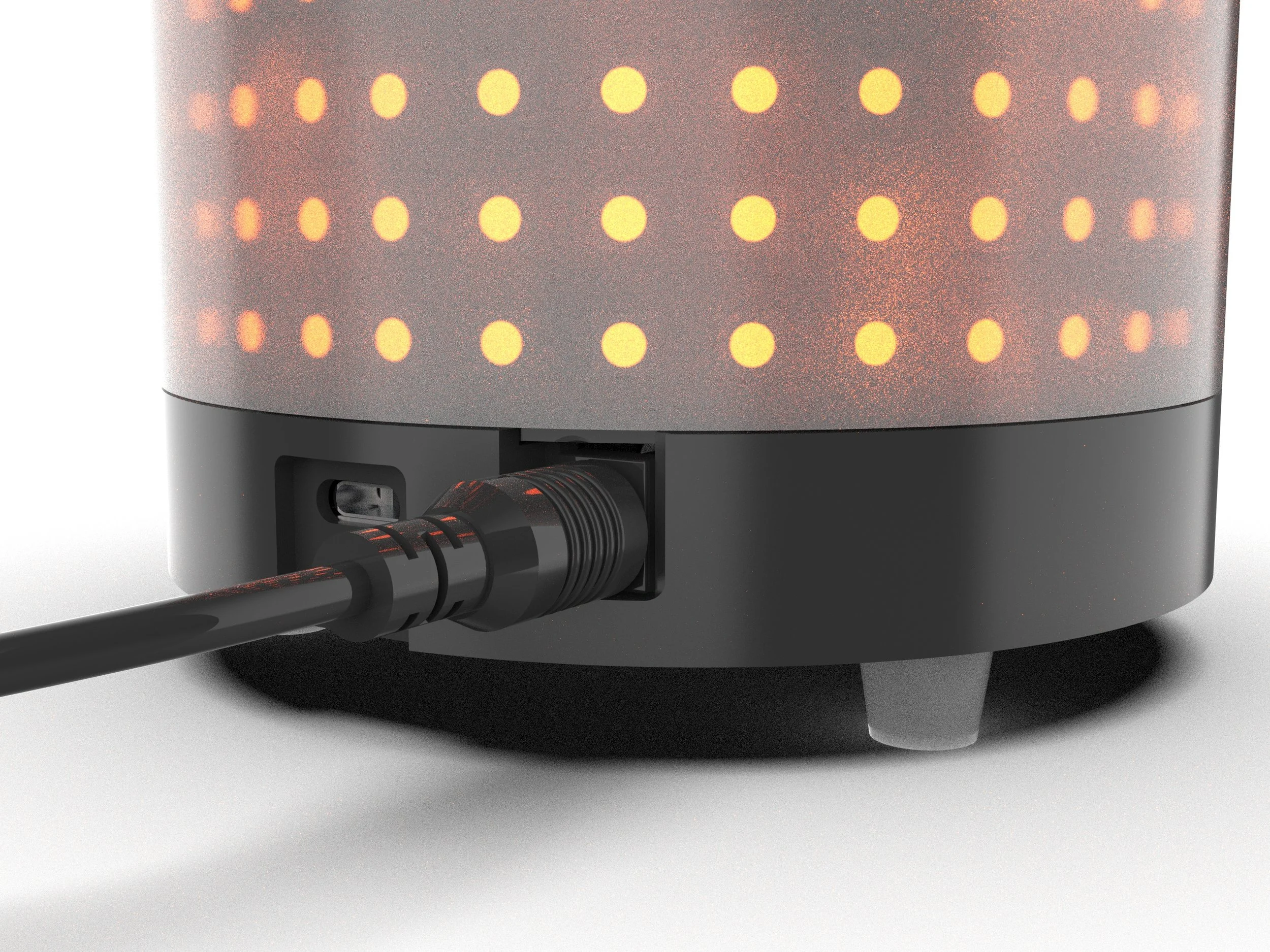

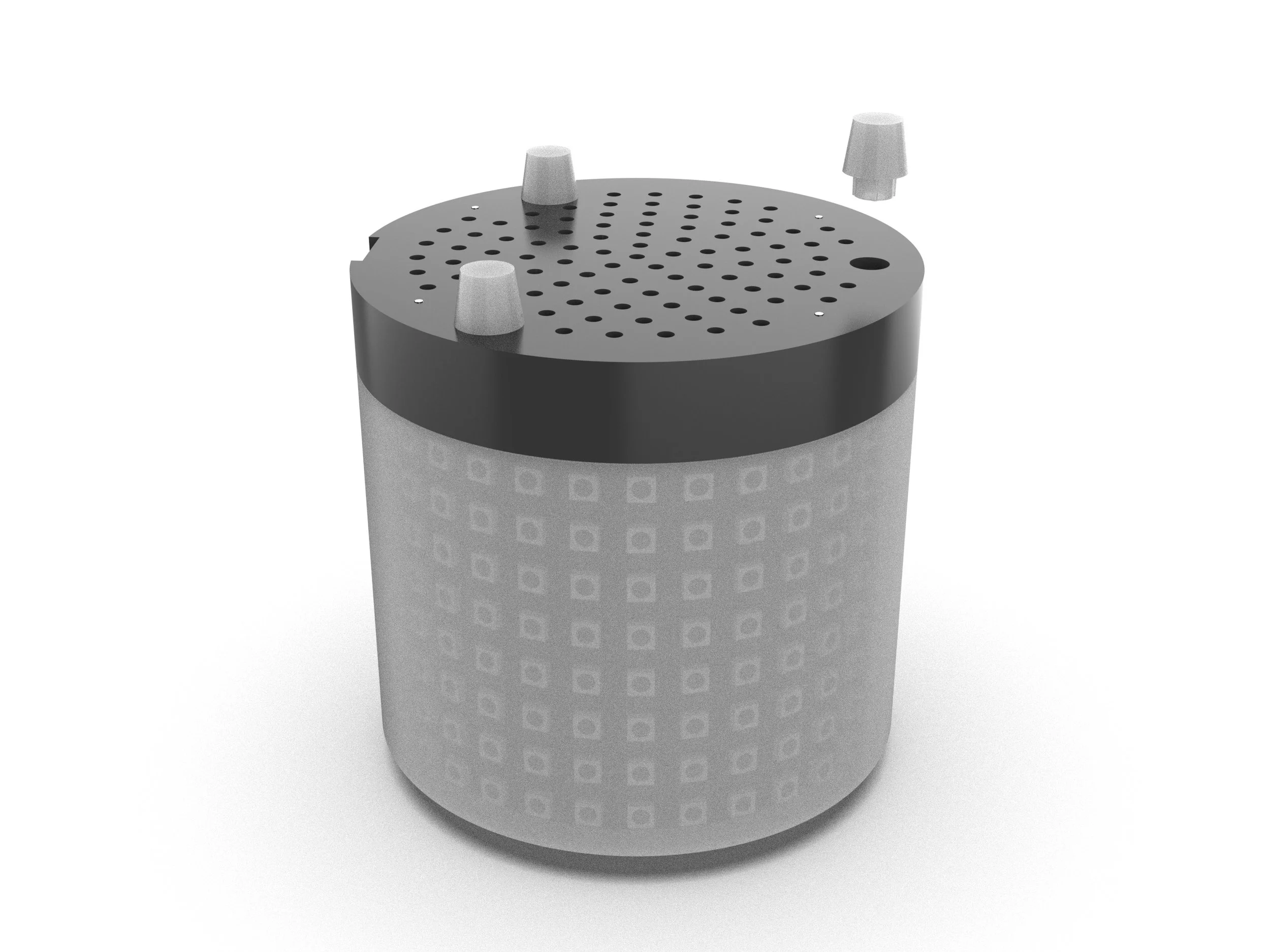

3D Design

The physical constraints of the Neopixel rings/matrix drive the primary dimensions of the form factor. The remaining effort was focused on electronics integration and design for ease of assembly (and 3D printing).

Functionality and material selection were also considered during this process and in sequencial refinements were tied to testing results

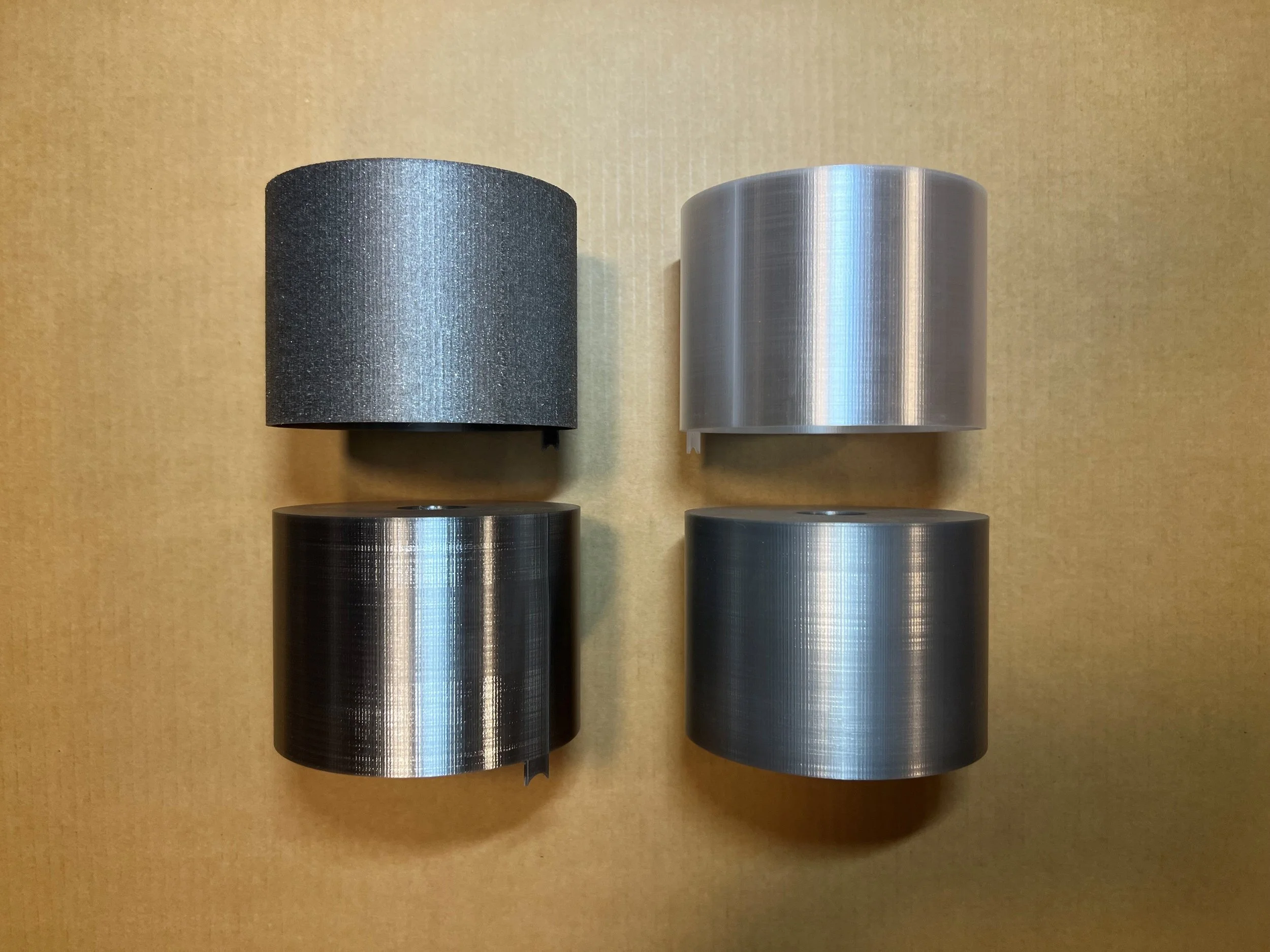

Testing / Material Selection

Prototype units were tested with all LEDs on (white) at full brightness. A temperature probe was installed to measure the internal temperature (which quickly exceeded the usable range of the PLA material). Modifications were made to the design (openings in the “tower” plus a PWM cooling fan) and material choice (ABS) to compensate.

Multiple materials and 3D printing parameters were explored to create the best possible appearance and performance for the LED passing through the “diffuser”.

Test probe with temperature sensor

Melted PLA housings - Mods to dissipate and mitigate heat damage

Material exploration to tune diffusion and withstand heat from LEDs

Documentation

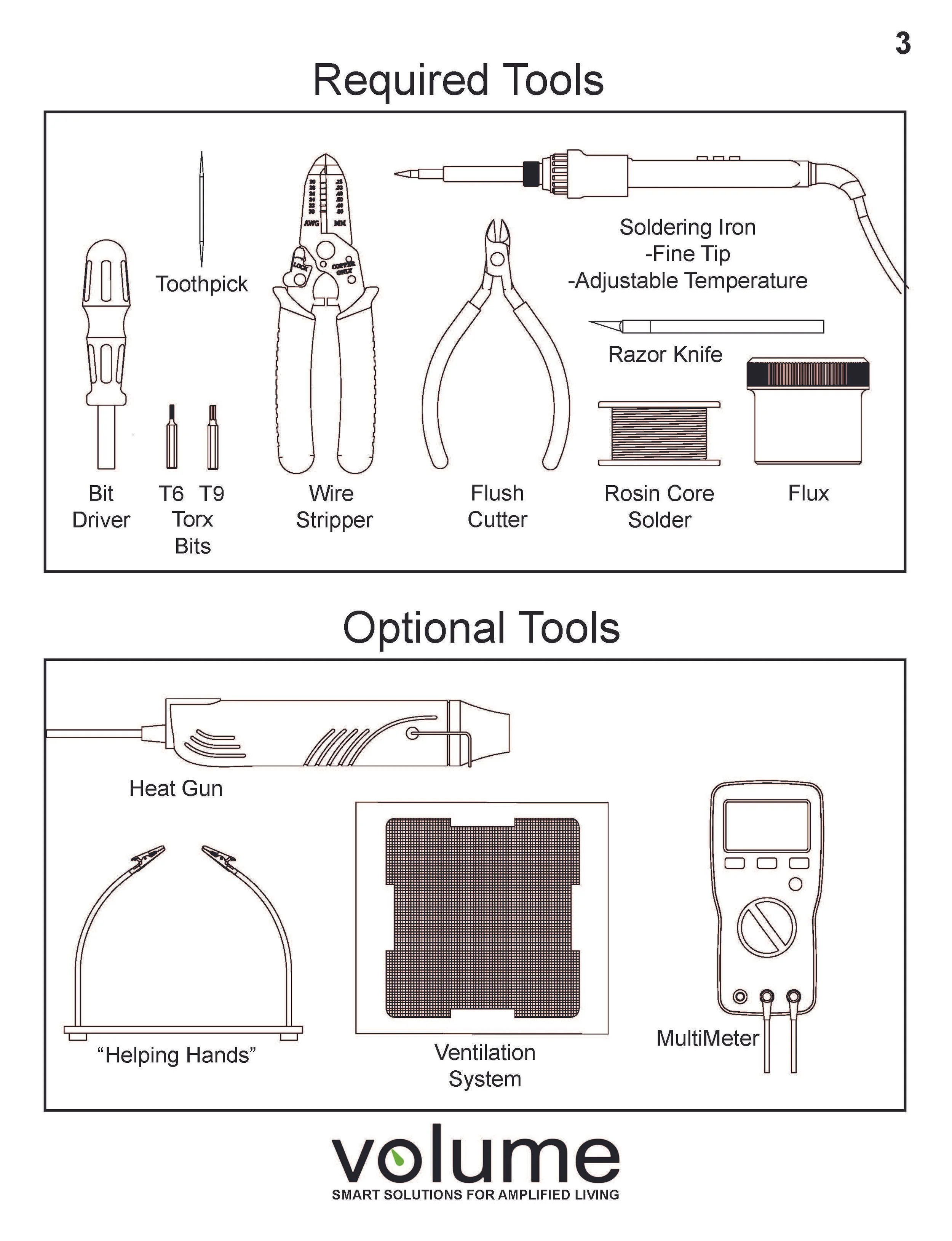

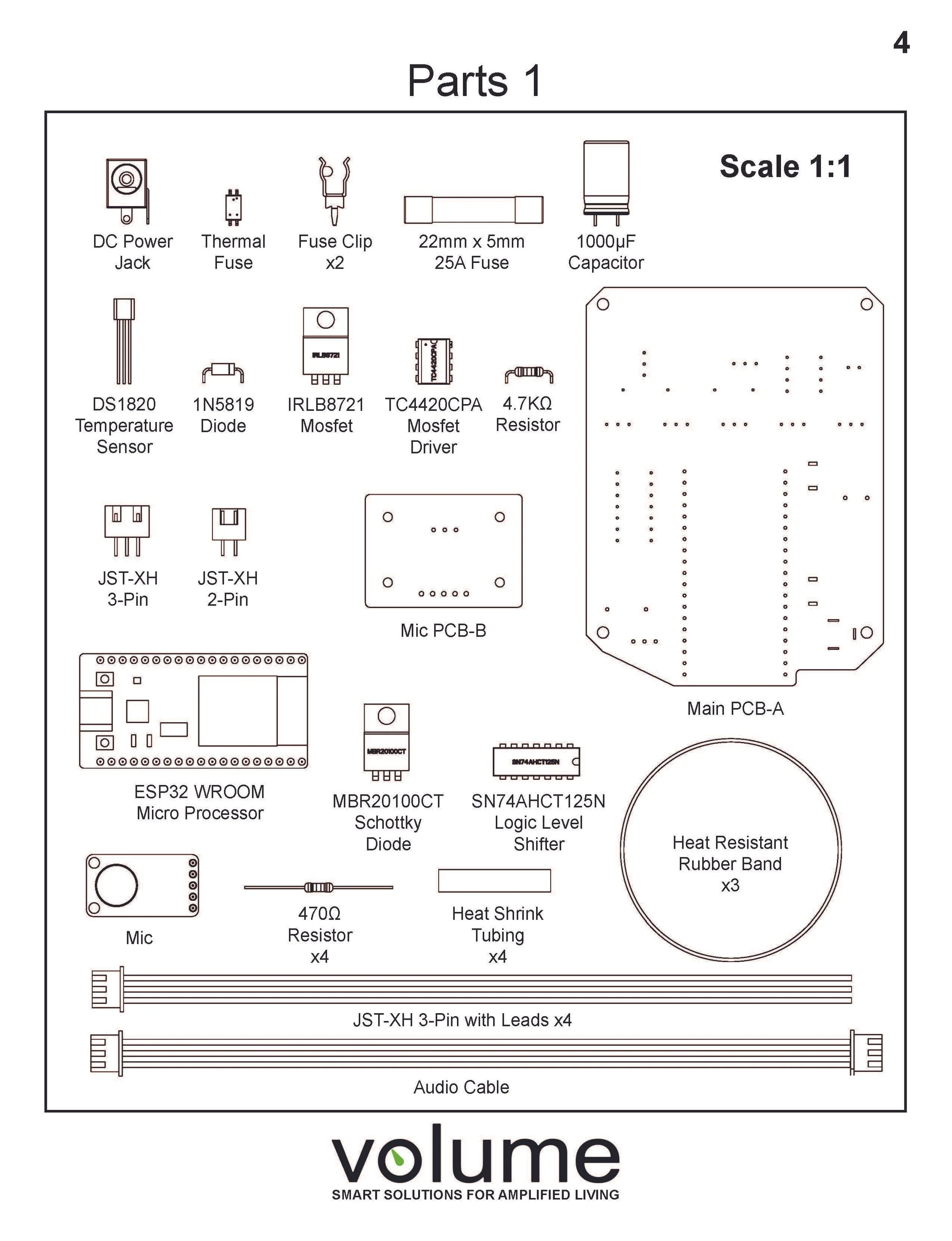

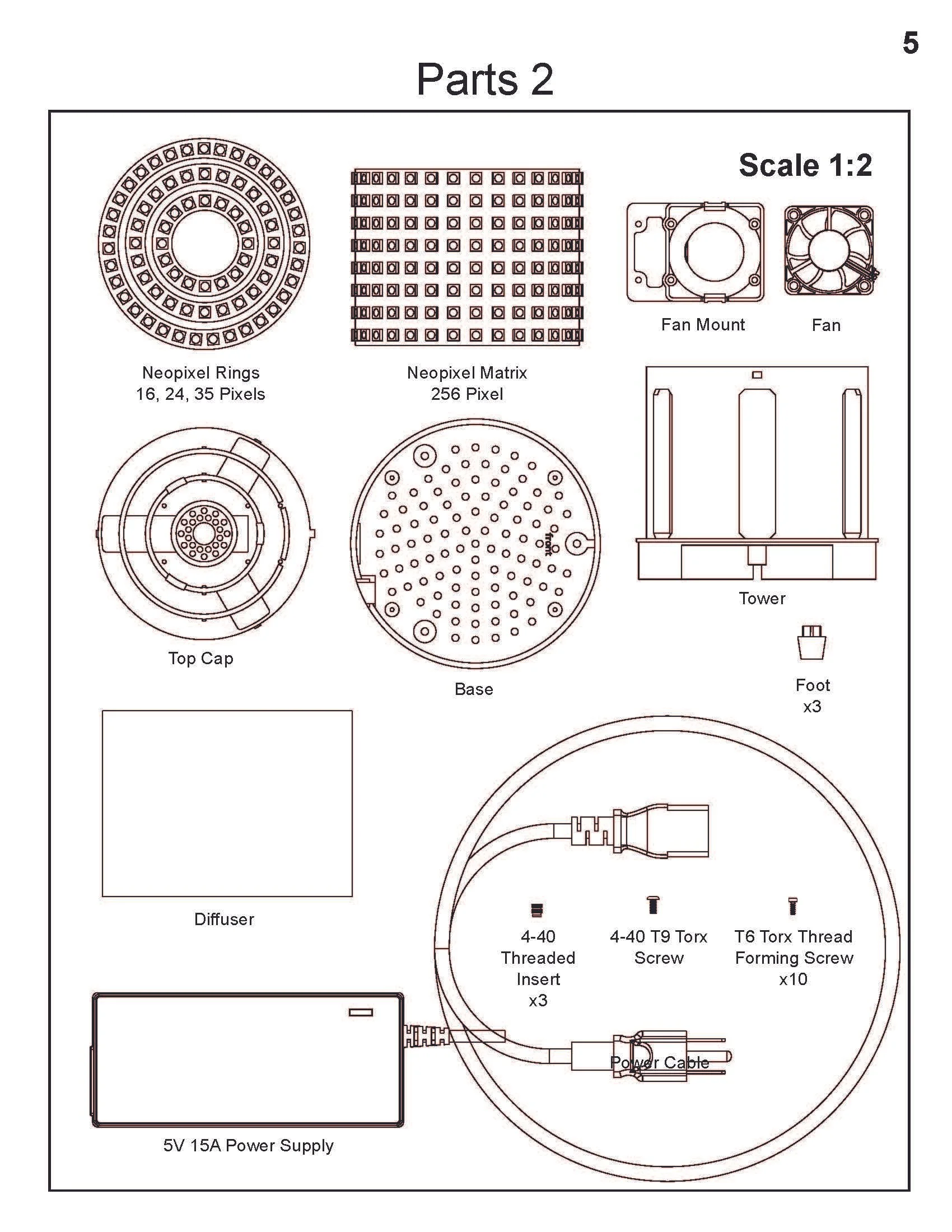

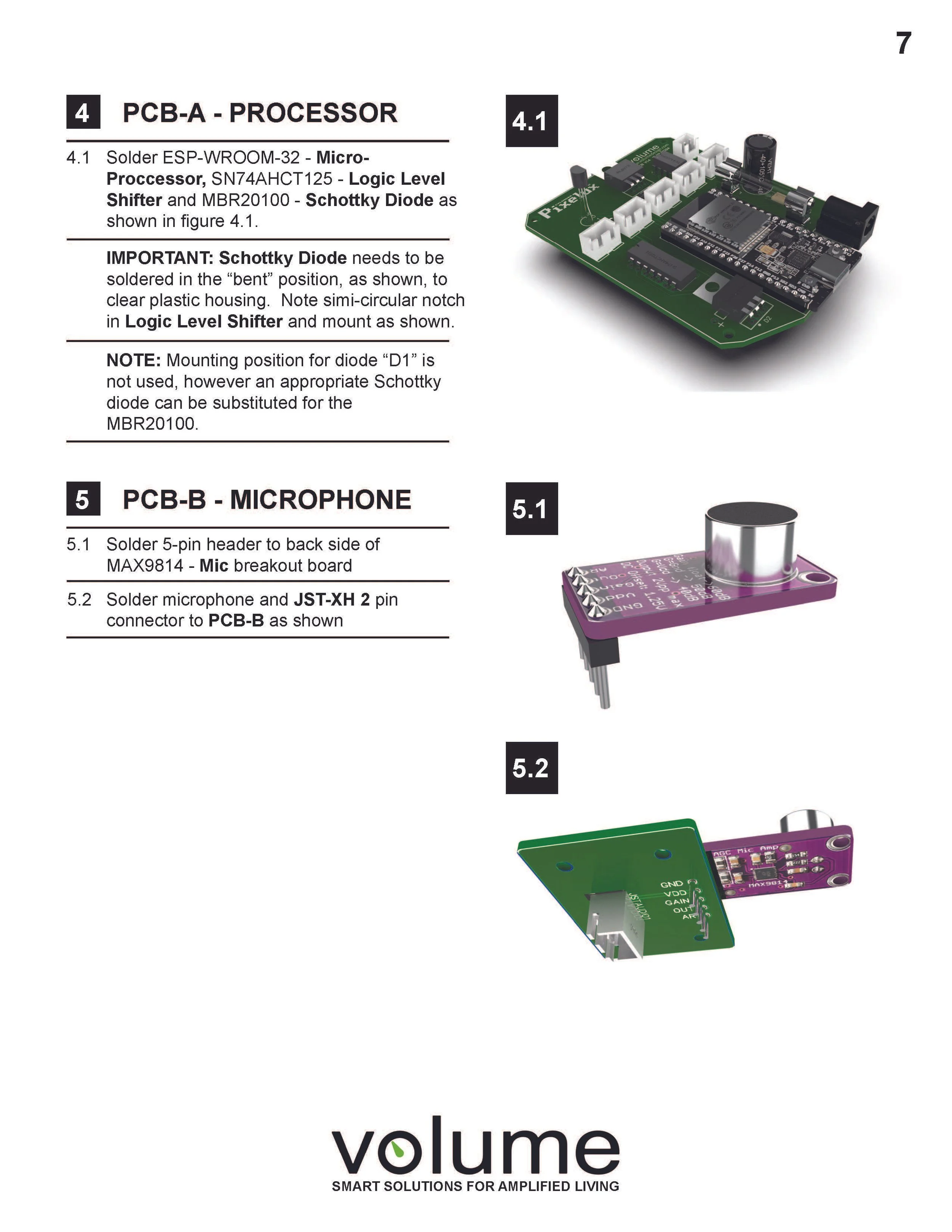

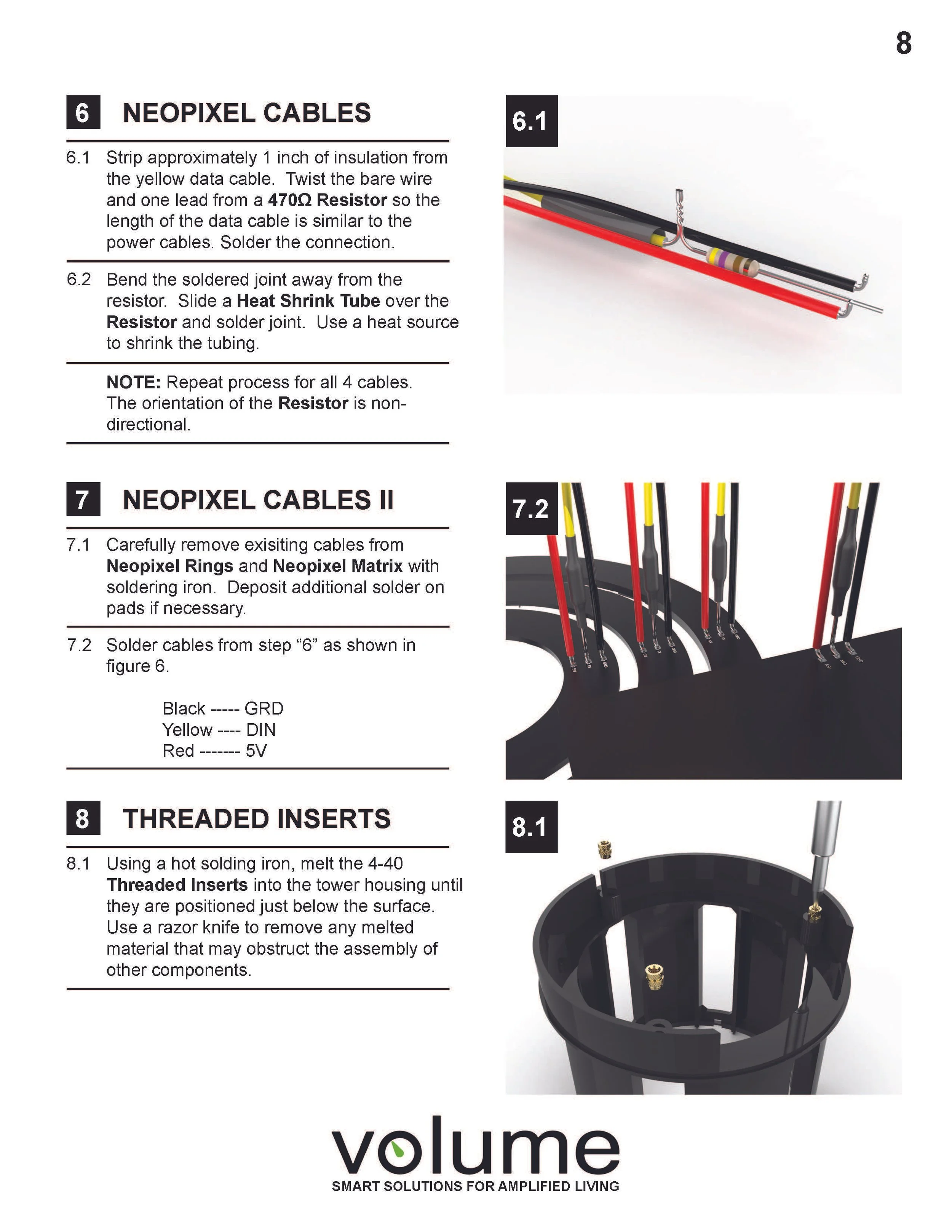

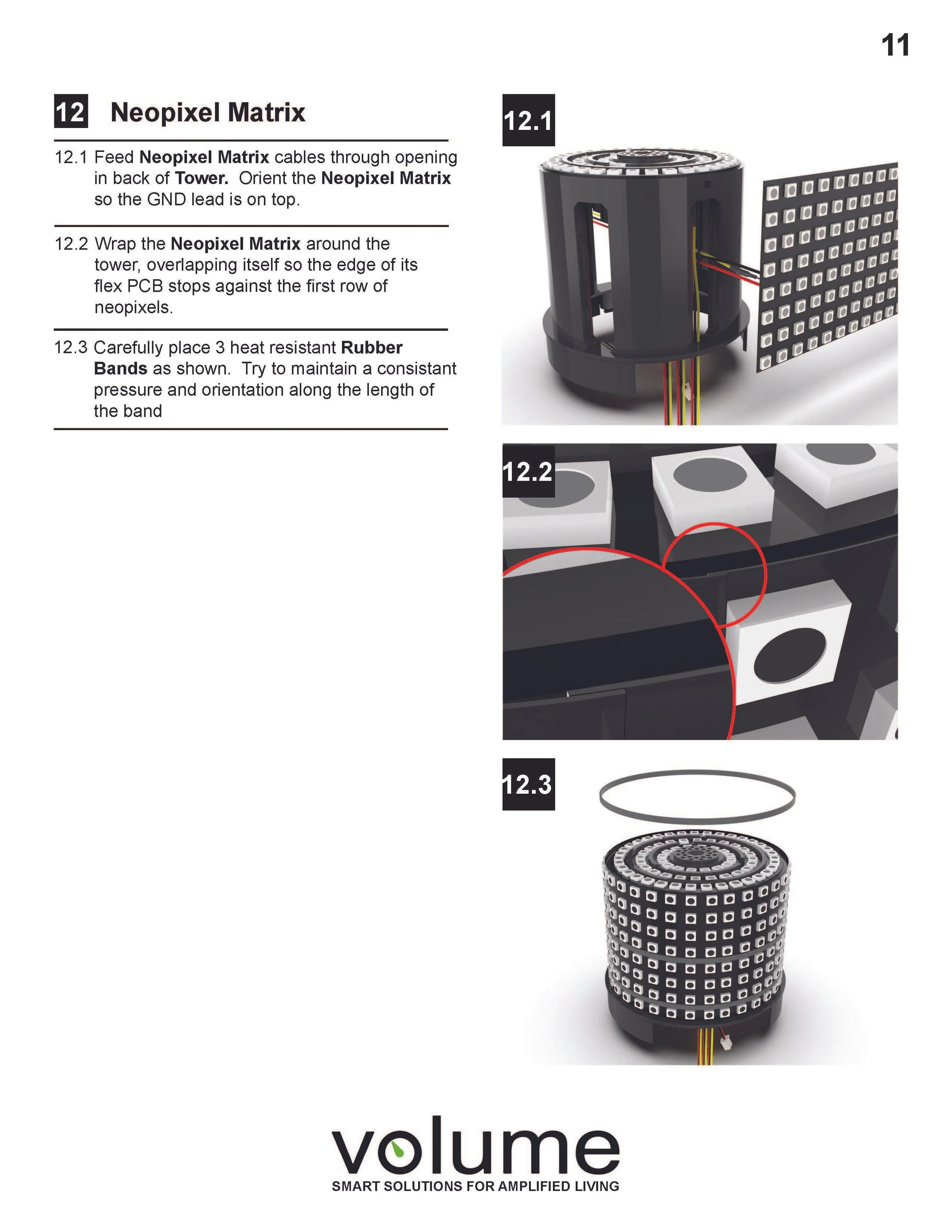

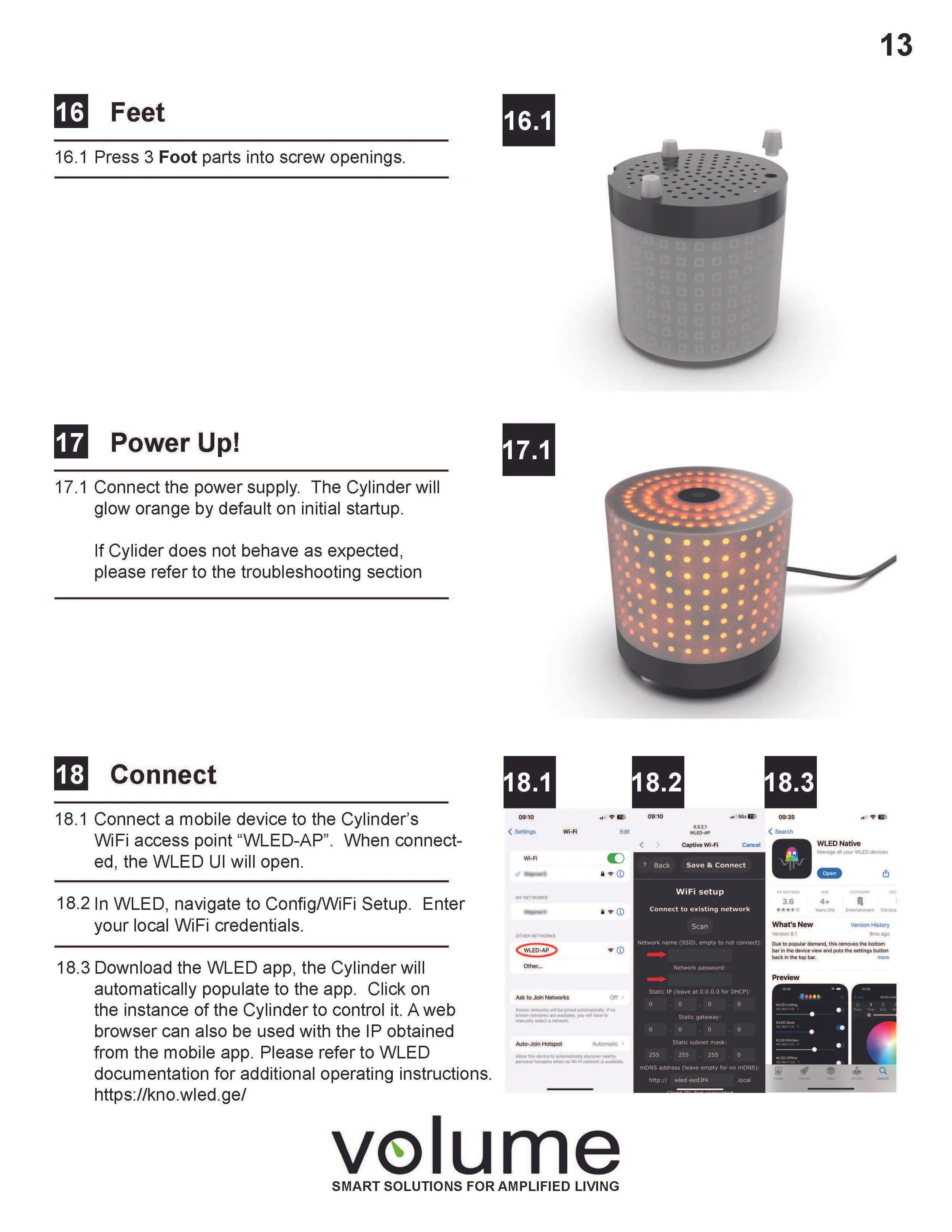

An assembly instruction guide was created so the device could be marketed as a DIY kit.

In addition to the liability and software license boilerplate, a tool and parts list are presented. Detailed, step by step assembly instructions with full color illustrations follow.

Finally, a quick “start-up'“ is described to get the device connected to WiFi and the WLED interface.

WLED Compilation

WLED is an open source program that drives and controls just about any LED type and/or configuration.

Pixelux - Cylinder contains three linear arrays of different lengths and an 8 x 32 matrix. No problem! A custom build of WLED was created to enable the 2D LED configuration, reactive audio microphone, pulse width modification fan and temperature sensor.

VisualStudio with platformIO was used to build a custom WLED binary to be flashed to the microprocessor with all the hardware user mods and GPIOs configured.

Pixelux - Cylinder Effects

There are thousands of awesome effects and color combinations to explore… here are just a few!